This article provides a comprehensive guide on sharpening a paralyzer spear, including essential tools, techniques, and safety tips to ensure optimal performance and longevity.

Understanding the Paralyzer Spear

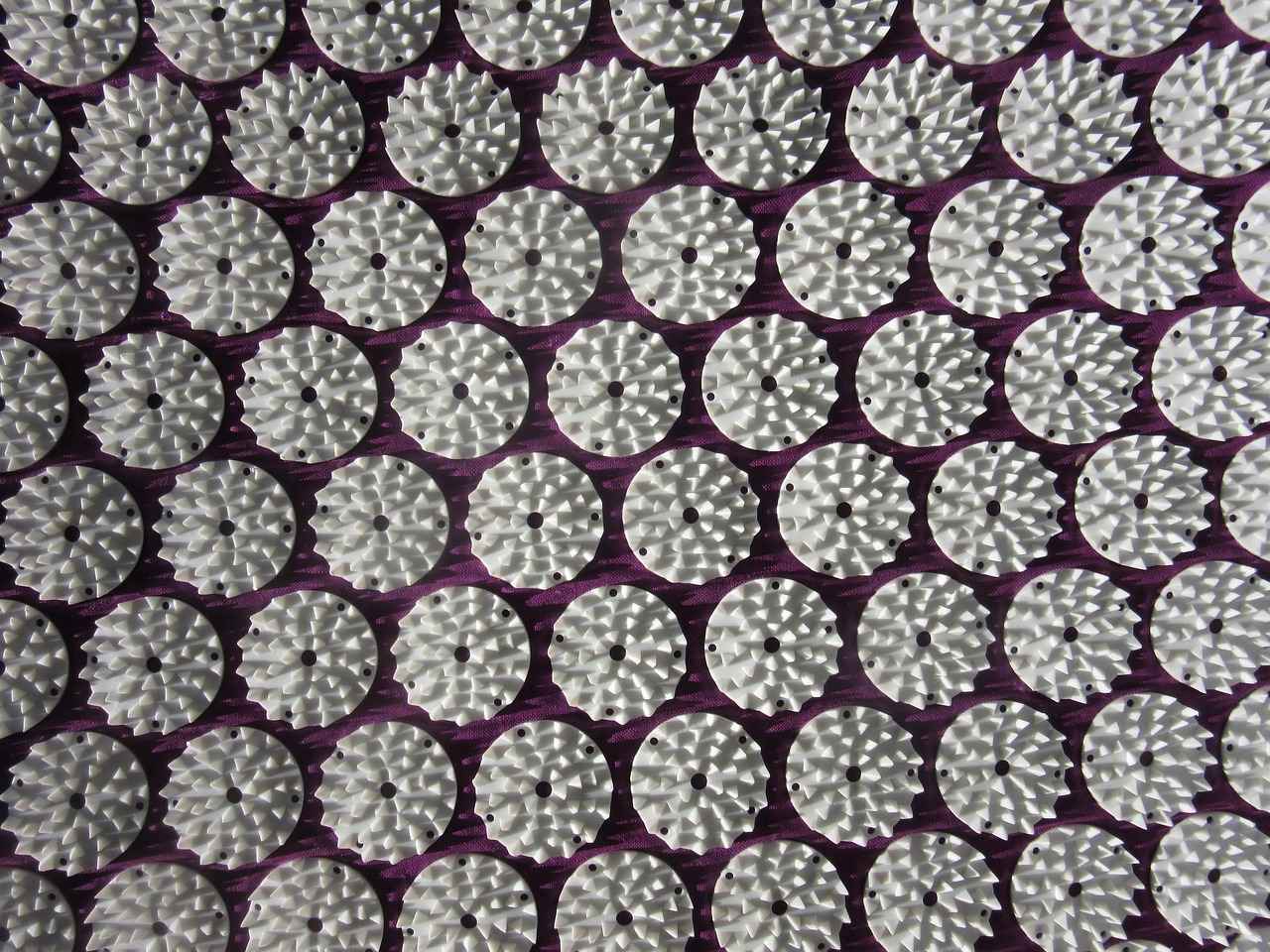

A paralyzer spear is uniquely designed for spearfishing, featuring multiple prongs that immobilize fish without piercing them. This design allows for a more humane catch, making it essential for responsible fishing practices. Understanding the spear’s structure and function is crucial before sharpening, as it influences the technique used.

Essential Tools for Sharpening

To effectively sharpen a paralyzer spear, you will need specific tools. The primary tools include:

- Files: Ideal for precision sharpening, files allow you to control the angle and pressure applied while sharpening the spear’s tips.

- Whetstones: A versatile option, whetstones can sharpen various materials and provide a smooth edge.

- Electric sharpeners: These are efficient for quick sharpening but require some skill to avoid over-sharpening.

Choosing the Right Grit

Selecting the appropriate grit is vital for achieving the desired sharpness. Coarse grits (around 200-400) are suitable for reshaping dull edges, while medium grits (600-1000) refine the edge. Fine grits (over 1000) polish the edge for a razor-sharp finish. Understanding when to use each grit will enhance your sharpening results.

Preparing Your Workspace

A well-organized workspace is essential for effective sharpening. Ensure you have:

- Good lighting: Adequate lighting helps you see the edge clearly, reducing the risk of accidents.

- Stable surface: A sturdy table or workbench prevents the spear from slipping during sharpening.

Safety Precautions

Safety should always be a priority when sharpening a spear. Here are some crucial precautions:

- Wear protective gloves to prevent cuts.

- Keep your workspace free of clutter to avoid accidents.

Step-by-Step Sharpening Process

Now that you have the right tools and workspace, let’s delve into the step-by-step process:

Step 1: Inspect the Spear

Before sharpening, thoroughly inspect the spear for any damage. Look for bent prongs or rust, as these issues should be addressed before proceeding.

Step 2: Secure the Spear

Securing the spear is vital for safety and precision. Use a vice or clamp to hold the spear firmly in place while you sharpen.

Step 3: Begin Sharpening

With the spear secured, start sharpening at a consistent angle. Apply even pressure and avoid over-sharpening, which can weaken the tips.

Testing the Sharpness

After sharpening, it’s essential to test the spear’s sharpness to ensure it meets your needs. Effective methods include:

- Visual Inspection: Look for a consistent edge without any dull spots.

- Cutting Tests: Safely test the spear’s cutting ability on soft materials to gauge sharpness.

Maintenance Tips for Longevity

Proper maintenance is key to prolonging the life of your paralyzer spear. Regular cleaning after each use can prevent rust and damage. Store your spear in a dry place, preferably in a protective case, to maintain its condition.

Common Mistakes to Avoid

Even experienced users can make mistakes when sharpening. Here are common pitfalls:

- Over-Sharpening: This can create weak points in the metal.

- Using the Wrong Tools: Ensure you select tools appropriate for your spear’s material to avoid damage.

Understanding the Paralyzer Spear

Before diving into sharpening techniques, it’s crucial to understand what a paralyzer spear is and its unique features that differentiate it from other types of spears. A paralyzer spear is specifically designed for underwater hunting, particularly in spearfishing. Unlike traditional spears that are often pointed for piercing, paralyzer spears are equipped with multiple prongs or barbs that are intended to immobilize fish rather than penetrate them. This design minimizes the risk of damaging the fish, allowing for a more humane catch.

The unique design of a paralyzer spear offers several advantages. Firstly, the multiple prongs create a larger surface area, which increases the chance of a successful catch. When the spear is thrust into the water, the prongs spread out, making it easier to ensnare fish that may be darting away. This is particularly beneficial in environments where visibility is low or where fish are skittish.

Another important feature of the paralyzer spear is the material from which it is made. Typically, these spears are constructed from durable materials such as stainless steel or high-grade aluminum, which resist corrosion and maintain sharpness over time. The tips of the spear are often specially designed to ensure that they can easily penetrate the water while remaining effective in capturing fish.

Additionally, the length of a paralyzer spear can vary, with longer models allowing for greater reach while hunting. However, the choice of length often depends on the specific fishing environment and the type of fish being targeted. For instance, in shallow waters, a shorter spear may be more manageable, while deeper waters may necessitate a longer spear for effective hunting.

It’s also worth noting that the weight of the spear plays a crucial role in its performance. A well-balanced spear will allow for easier maneuverability and less fatigue during extended use. Many experienced spearfishers recommend finding a spear that feels comfortable in hand, as this can significantly impact accuracy and control during a dive.

In summary, understanding the paralyzer spear’s unique features—its design, material, length, and weight—provides a solid foundation for anyone looking to enhance their spearfishing experience. By recognizing these characteristics, users can better appreciate the importance of proper maintenance and sharpening techniques, ensuring their spear remains an effective tool in the water.

Essential Tools for Sharpening

When it comes to sharpening a paralyzer spear, having the right tools is crucial for achieving the best results. This section explores the various tools necessary for the sharpening process and their specific roles, ensuring that both novice and experienced users can effectively maintain their equipment.

- Files: Files are a traditional and reliable choice for sharpening metal tips. They come in various shapes and sizes, allowing for precision work on different parts of the spear. The flat file is ideal for broad surfaces, while a round file is perfect for the tips and edges. Using files requires a steady hand and a keen eye, making them suitable for those who appreciate a hands-on approach.

- Whetstones: Whetstones are another popular option, known for their versatility. They can be used on various materials, including steel and aluminum. The key to using a whetstone is to maintain the correct angle while applying consistent pressure. This tool requires some practice to master but offers a smooth edge that enhances the spear’s cutting ability.

- Electric Sharpeners: For those looking for convenience, electric sharpeners can save time and effort. These devices often come with preset angles, making them user-friendly for beginners. However, they may not provide the same level of precision as manual tools, and users should be cautious not to overheat the blade during the sharpening process.

- Diamond Stones: Diamond sharpening stones are highly effective for quickly honing a blade. They come in various grits, allowing users to choose the right level of abrasiveness for their needs. These stones are durable and can be used on hard materials, making them a valuable addition to any sharpening toolkit.

- Leather Strops: After sharpening, using a leather strop can help achieve a razor-sharp edge. This tool polishes the blade, removing any small burrs left after sharpening. It’s a simple yet effective way to enhance the spear’s performance, ensuring it’s ready for action.

In addition to the tools mentioned above, it’s important to have a few accessories on hand:

- Safety Gear: Always wear protective gloves and goggles when sharpening to prevent injuries.

- Work Surface: A stable and well-lit workspace is essential for effective sharpening. Ensure your area is organized and free from distractions.

- Cleaning Supplies: After sharpening, clean your tools and the spear to remove metal shavings and debris, which can cause rust and damage over time.

By equipping yourself with the right tools and accessories, you can significantly improve your sharpening process. Each tool plays a unique role in maintaining the spear’s performance, ensuring that it remains effective for your spearfishing adventures.

Types of Sharpening Tools

When it comes to sharpening a paralyzer spear, the choice of tools is crucial for achieving the desired edge. Different tools offer unique benefits, and understanding these can significantly enhance your sharpening experience. Below, we will explore various sharpening tools, their advantages, and potential drawbacks, ensuring you select the right one for your needs.

- Files: Files are a traditional sharpening tool, ideal for those who prefer a hands-on approach. They come in various shapes and sizes, allowing for precision in sharpening metal tips. The tactile feedback they provide helps users gauge the amount of material being removed, making them suitable for both beginners and experienced sharpeners. However, using files requires a steady hand and can be time-consuming.

- Whetstones: Whetstones are versatile sharpening tools that can be used on different materials, including steel and ceramic. They provide a smooth edge and are favored for their ability to produce a fine finish. The learning curve may be steeper compared to files, as proper technique is essential for effective sharpening. Users must master the angle and pressure to achieve optimal results. Whetstones come in various grits, allowing for tailored sharpening, but they require maintenance and regular flattening.

- Electric Sharpeners: For those seeking convenience and speed, electric sharpeners are an excellent choice. They automate the sharpening process, making it quick and efficient. Electric sharpeners often come with built-in guides to maintain the correct angle, minimizing the risk of damaging the spear. However, they may remove material too quickly for some users’ preferences and can lead to over-sharpening if not used cautiously.

- Honing Rods: While not a sharpening tool in the traditional sense, honing rods are essential for maintaining an already sharp edge. They realign the blade’s edge, ensuring optimal performance between sharpening sessions. They are easy to use and can extend the time between full sharpening, making them a valuable addition to your toolkit.

In conclusion, the choice of sharpening tool significantly affects the outcome of your sharpening process. While files and whetstones offer a more traditional approach that requires skill and patience, electric sharpeners provide speed and convenience. Understanding the advantages and disadvantages of each tool will help you make an informed decision that best suits your skill level and the material of your paralyzer spear.

Files: The Traditional Choice

When it comes to sharpening metal tips, files have long been regarded as a classic and reliable option. Their design allows for precision and control, making them suitable for both beginners and seasoned users. Unlike other sharpening tools that may require advanced techniques, files offer a straightforward approach to achieving a sharp edge on your paralyzer spear.

Files come in various shapes and sizes, each catering to different sharpening needs. The most common types include flat, round, and triangular files. Flat files are ideal for broad surfaces, while round files excel in reaching into tight corners or curves. Triangular files are perfect for sharpening serrated edges. This variety ensures that users can select the right file for their specific requirements, enhancing their sharpening experience.

One significant advantage of using files is their manual operation. This feature allows users to have complete control over the sharpening process. By adjusting the angle and pressure applied during sharpening, you can tailor the edge to your desired sharpness. This level of control is especially beneficial for those who are just starting, as it allows for a more forgiving learning curve.

| Type of File | Best For |

|---|---|

| Flat File | Broad edges and flat surfaces |

| Round File | Curved edges and tight spaces |

| Triangular File | Serrated edges |

Additionally, files are relatively affordable and widely available, making them an accessible choice for anyone looking to sharpen their tools. They require minimal maintenance and can last for years if used correctly. This durability is a significant factor for users who want a dependable tool that won’t let them down.

However, it is essential to understand that while files are effective, they do have limitations. They may not be suitable for all types of materials, and the sharpening process can be time-consuming, particularly for those who need to remove a lot of material. Nonetheless, for those seeking a traditional and reliable method of sharpening, files remain an excellent choice.

In conclusion, files offer a unique blend of precision, control, and affordability that makes them a preferred tool for sharpening metal tips. Whether you are a beginner or an experienced user, mastering the use of files can significantly enhance your sharpening skills and ensure your paralyzer spear remains in optimal condition.

Whetstones: A Versatile Option

Whetstones, often referred to as sharpening stones, are a favored tool among craftsmen and hobbyists for achieving a sharp edge on various implements. Their versatility makes them an excellent choice for sharpening not only knives but also tools like paralyzer spears, chisels, and axes. Understanding how to effectively use a whetstone can significantly enhance the performance of your tools and extend their longevity.

Types of Whetstones

Whetstones come in various types, each designed for specific sharpening needs. The most common types include:

- Oil Stones: These stones require oil for lubrication during the sharpening process. They are often made of aluminum oxide or silicon carbide, providing a fine edge.

- Water Stones: As the name suggests, these stones use water as a lubricant. They tend to cut faster than oil stones and are available in various grits.

- Synthetic Stones: Made from man-made materials, these stones can mimic natural stones and offer consistent performance. They are often more affordable and come in various grits.

- Natural Stones: Sourced from quarries, these stones have unique properties that can provide a superior edge. However, they can be more expensive and less consistent than synthetic options.

Choosing the Right Grit

Selecting the appropriate grit for your whetstone is crucial for achieving the desired sharpness. Grit is measured on a scale, with lower numbers indicating coarser stones and higher numbers indicating finer stones. For sharpening a paralyzer spear, consider the following:

- Coarse Grit (200-600): Ideal for repairing damaged edges or reshaping blades.

- Medium Grit (800-2000): Suitable for general sharpening and creating a sharp edge.

- Fine Grit (3000 and above): Best for honing and polishing the edge to a razor-sharp finish.

Sharpening Technique

To effectively sharpen your paralyzer spear using a whetstone, follow these steps:

1. Soak the whetstone (if it's a water stone) for about 10-15 minutes before use.2. Secure the spear in a stable position.3. Hold the spear at a consistent angle, typically around 20 degrees.4. Using light pressure, slide the spear along the stone in a sweeping motion, ensuring even coverage.5. Alternate sides to maintain a balanced edge.6. Rinse the stone periodically to remove metal filings and debris.7. After achieving the desired sharpness, wipe the spear clean and check the edge.

Practice Makes Perfect

While using a whetstone may seem daunting at first, practice is key to mastering this skill. Start with inexpensive tools to build your confidence before moving on to more valuable equipment. Over time, you will develop a feel for the right angle and pressure needed to achieve a sharp edge.

Conclusion

Whetstones are a versatile and effective option for sharpening a variety of tools, including paralyzer spears. By understanding the different types of whetstones, selecting the right grit, and employing proper sharpening techniques, you can ensure that your tools remain in optimal condition. With a bit of practice, you’ll find that using a whetstone not only enhances the performance of your tools but also provides a satisfying and rewarding experience.

Choosing the Right Grit

Selecting the appropriate grit for your sharpening tool is vital in achieving the best results when sharpening your paralyzer spear. The grit level of a sharpening tool refers to the size of the abrasive particles on its surface, which directly influences the effectiveness and efficiency of the sharpening process. Understanding the different grit levels and their specific applications is essential for both novice and experienced sharpeners.

- Coarse Grit (Below 400): Coarse grits are typically used for initial sharpening, especially if the blade is extremely dull or damaged. This grit level quickly removes material, reshaping the edge of the spear. However, it is important to use coarse grit sparingly, as it can lead to a rough edge if overused.

- Medium Grit (400-1000): Medium grit is ideal for general sharpening and is often the go-to option for maintaining an already sharp edge. It strikes a balance between material removal and edge refinement. This grit is perfect for creating a sharper edge without excessively altering the spear’s profile.

- Fine Grit (1000-3000): Fine grits are used for honing and polishing the edge after sharpening with coarser grits. This level helps to refine the edge, making it smoother and sharper. It is particularly useful for achieving a clean and precise edge that enhances the spear’s performance.

- Extra Fine Grit (Above 3000): Extra fine grits are reserved for final polishing and are often used by professionals. This grit level produces a razor-sharp edge and is perfect for specialized tasks that require precision. Using extra fine grit can significantly improve the spear’s cutting ability, making it an excellent choice for those seeking top-notch performance.

When choosing the right grit, consider the current condition of your spear. If it has nicks, chips, or is very dull, starting with a coarse grit is advisable. For regular maintenance, medium grit is often sufficient. If you are looking to refine and polish your edge, transition to fine or extra fine grits.

Additionally, the material of your spear tip can influence your choice of grit. For example, stainless steel tips may require different grit levels compared to carbon steel tips. Always ensure that the grit you choose aligns with the material to prevent damage and achieve optimal results.

In summary, understanding the different grit levels and their appropriate applications is crucial for effective sharpening. By selecting the right grit, you can enhance the performance and longevity of your paralyzer spear, ensuring it remains a reliable tool for your spearfishing adventures.

Preparing Your Workspace

A well-organized workspace is crucial for effective sharpening of a paralyzer spear. Setting up your area correctly not only enhances safety but also improves efficiency during the sharpening process. Below are essential tips on how to create an optimal workspace.

- Choose the Right Location: Select a well-ventilated area with ample space to work comfortably. Avoid cluttered environments that can distract you or create hazards.

- Stable Surface: Use a sturdy table or workbench that can securely hold your spear and sharpening tools. A stable surface minimizes the risk of accidents and allows for better control during sharpening.

- Proper Lighting: Ensure your workspace is well-lit. Good lighting helps you see the spear’s edge clearly, allowing for more precise sharpening. Consider using a combination of overhead lights and task lighting directed at your work area.

- Organize Your Tools: Keep all necessary sharpening tools within reach. Use a toolbox or organizer to store files, whetstones, and other equipment. This not only saves time but also prevents you from misplacing essential items.

- Safety Gear: Always wear appropriate safety gear, such as gloves and eye protection. This is particularly important when working with sharp tools and materials.

- Minimize Distractions: Turn off any distractions such as loud music or television. Focus on the task at hand to ensure you remain attentive and safe.

Creating a Safe Environment

To further enhance safety in your workspace, consider implementing the following practices:

1. Keep a first aid kit nearby for any minor injuries.2. Ensure that your workspace is free from spills or debris that could cause slips or falls.3. If using electrical sharpeners, check for frayed cords and ensure that outlets are safe.4. Have a fire extinguisher accessible if you are working with flammable materials.

Testing Your Setup

Before starting the sharpening process, take a moment to test your setup. Sit in front of your workspace and ensure that everything is within reach. Check that your tools are organized and that you can easily access them without having to move around too much. This preparation will not only save time but also enhance your sharpening experience.

By following these guidelines for preparing your workspace, you can ensure a safe and efficient environment for sharpening your paralyzer spear. A well-structured area allows you to focus on the task, ultimately leading to better results and a sharper spear.

Safety Precautions

When sharpening a paralyzer spear, it is essential to prioritize safety. The process involves sharp tools and potentially hazardous situations, making it crucial to adopt effective safety measures. This section outlines vital precautions to prevent accidents and injuries while working with your spear.

- Wear Protective Gear: Always wear appropriate protective gear, such as safety goggles and gloves. Goggles protect your eyes from flying debris, while gloves provide a firm grip and shield your hands from sharp edges.

- Work in a Well-Lit Area: Ensure your workspace is well-lit. Good lighting helps you see clearly, reducing the chances of accidents due to misjudgment or lack of visibility.

- Use a Stable Work Surface: A sturdy, flat surface is vital for sharpening. This prevents the spear from slipping and ensures precise control during the sharpening process.

- Keep Your Tools Organized: Maintain an organized workspace. Keep your sharpening tools within reach and avoid clutter, as this can lead to accidents.

- Secure the Spear: Always secure the spear before sharpening. Use clamps or a vise to hold the spear firmly in place. This minimizes movement and enhances safety while you work.

- Maintain Focus: Concentration is key when sharpening tools. Avoid distractions and stay focused on the task at hand to prevent accidents.

- Follow Manufacturer Guidelines: Always adhere to the manufacturer’s instructions for sharpening tools. This ensures you use the tools correctly and safely.

- Inspect Tools Regularly: Regularly check your sharpening tools for wear and tear. Damaged tools can lead to accidents, so replace them as needed.

- Have a First Aid Kit Nearby: Accidents can happen, even with precautions in place. Keep a first aid kit close by to address any minor injuries promptly.

Implementing these safety precautions not only protects you but also enhances the sharpening process, allowing you to achieve better results. Remember, the goal is to sharpen effectively without compromising your safety.

In conclusion, safety should never be overlooked when sharpening a paralyzer spear. By following these guidelines, you can ensure a safer sharpening experience that allows you to focus on achieving the perfect edge for your spear.

Lighting and Stability

When it comes to sharpening a paralyzer spear, the environment in which you work is just as important as the tools you use. Proper lighting and a stable surface are crucial for achieving the best results. In this section, we will explore how to create optimal conditions for sharpening your spear, ensuring accuracy and safety throughout the process.

Good lighting is essential when sharpening your spear. It allows you to clearly see the blade’s edge and any imperfections that may require attention. Here are some key points to consider regarding lighting:

- Natural Light: Whenever possible, try to work in natural light. Daylight provides the best visibility, allowing you to see the finer details of the spear’s edge.

- Artificial Lighting: If natural light isn’t available, use bright, white LED lights. Avoid dim or yellow lights, as they can obscure details and make it harder to assess the sharpness of the blade.

- Positioning: Position your light source to minimize shadows. This can be achieved by placing the light at an angle that illuminates the blade without creating glare.

In addition to proper lighting, having a stable surface is vital for effective sharpening. A secure workspace helps prevent accidents and ensures precision. Here are some tips for achieving stability:

- Workbench: Use a sturdy workbench or table that can withstand pressure. Ensure it is at a comfortable height to avoid strain while sharpening.

- Non-Slip Mats: Consider using non-slip mats or clamps to secure the spear in place. This prevents movement and allows you to focus on the sharpening process without distractions.

- Clear Clutter: Keep your workspace clean and free of clutter. A tidy area reduces the risk of accidents and allows you to work more efficiently.

By combining proper lighting with a stable surface, you create an ideal environment for sharpening your paralyzer spear. This synergy not only enhances your ability to see the blade clearly but also allows for greater control during the sharpening process. Remember, the goal is to achieve a sharp edge that performs well during use.

Investing time in setting up your workspace with adequate lighting and stability will significantly improve your sharpening experience. By following these tips, you can ensure that your paralyzer spear is sharpened accurately and safely, ready for your next adventure.

Step-by-Step Sharpening Process

Now that you have the right tools and workspace, it’s time to explore the step-by-step process of sharpening a paralyzer spear to achieve a razor-sharp edge. This process involves several crucial steps that ensure your spear maintains its effectiveness and longevity. Each step requires attention to detail, so let’s break it down.

- Step 1: Inspect the Spear

Before you start sharpening, it is essential to conduct a thorough inspection of your paralyzer spear. Look for any visible signs of damage, such as bends, cracks, or rust. Addressing these issues first will help you avoid compromising the spear’s integrity during the sharpening process. If you find any significant damage, consider repairing it before proceeding.

- Step 2: Secure the Spear

Safety and precision are paramount when sharpening your spear. Secure the spear in a stable position using a vise or clamps. This will prevent any movement while you work, allowing for more controlled sharpening. Ensure that the spear’s tip is facing away from you to minimize the risk of injury.

- Step 3: Begin Sharpening

With your spear secured, it’s time to begin sharpening. Depending on the tool you’re using, the technique may vary. If you’re using a file, hold it at a consistent angle of about 20 degrees against the spear tip. Apply even pressure as you move the file along the edge. For whetstones, ensure you lubricate the stone with water or oil as recommended. Use a back-and-forth motion, maintaining the same angle to achieve a uniform edge.

- Step 4: Check Your Progress

It’s important to frequently check your progress during the sharpening process. Stop periodically to visually inspect the edge. Look for a shiny, consistent surface that indicates you’re removing material evenly. If you notice any dull spots, focus on those areas until they are sharpened.

- Step 5: Final Touches

After achieving the desired sharpness, it’s time for the final touches. Use a finer grit stone or a strop to polish the edge. This step enhances the sharpness and reduces the risk of chipping. Always ensure that the final angle remains consistent with your initial sharpening angle.

- Step 6: Clean Up

Once sharpening is complete, clean the spear thoroughly to remove any metal filings or debris. Use a soft cloth and a mild detergent if necessary. Dry the spear completely to prevent rusting. Proper cleaning is essential for maintaining the spear’s condition and ensuring its longevity.

By following these detailed steps, you can effectively sharpen your paralyzer spear, ensuring it is always ready for use. Remember that practice makes perfect, so don’t hesitate to refine your technique over time.

Step 1: Inspect the Spear

Before you embark on the sharpening process, it is crucial to thoroughly inspect your paralyzer spear for any signs of damage or wear. This initial step is not just a formality; it sets the foundation for a successful sharpening experience. By identifying any issues early, you can effectively address them, ensuring that your spear performs optimally when you need it.

- Check the Tip: Examine the spear’s tip for any nicks, bends, or dullness. A damaged tip can significantly affect the spear’s piercing ability and overall performance.

- Inspect the Shaft: Look along the shaft for cracks or signs of wear. A compromised shaft can lead to breakage during use, which is dangerous.

- Examine the Handle: Ensure that the handle is secure and free from cracks. A loose or damaged handle can make the spear difficult to control.

- Look for Rust: Check for any rust spots, especially on the metal parts of the spear. Rust can weaken the material and affect the spear’s integrity.

Addressing these issues before sharpening is essential. For instance, if you find that the tip is damaged, sharpening it without fixing the underlying problem will only exacerbate the issue. Instead, consider using a file or a grinder to reshape the tip before proceeding with the sharpening process.

Furthermore, if the shaft is bent, you may need to straighten it or replace it entirely. This will not only improve the spear’s performance but will also enhance your safety while using it. Remember, a spear that is not in good condition can lead to accidents, which is why thorough inspection is paramount.

In addition to physical inspections, it is also wise to consider the spear’s history. If the spear has been used extensively, it may require more attention than a newer one. Always be mindful of how you have used the spear in the past, as this can provide insight into potential issues that may not be immediately visible.

Once you have completed the inspection and addressed any concerns, you can confidently move on to the next steps in the sharpening process. This attention to detail not only prolongs the life of your spear but also ensures that it remains a reliable tool for your spearfishing adventures.

Step 2: Secure the Spear

Securing the spear is a crucial step in the sharpening process, as it ensures both safety and precision. Without proper stabilization, you risk injury and may compromise the effectiveness of your sharpening efforts. Here, we will explore various effective methods to hold the spear in place during sharpening, ensuring a safe and efficient experience.

- Using a Spear Vise: A spear vise is an excellent tool for securing your spear. It grips the spear firmly while allowing you to adjust the angle easily. This tool is particularly beneficial for those who sharpen their spear frequently, as it provides a consistent and stable platform.

- Clamping Techniques: If a vise is unavailable, using clamps can be an effective alternative. Place the spear on a stable surface, such as a workbench, and use clamps to hold it in place. Ensure the clamps do not damage the spear’s surface, and adjust them to hold the spear securely without excessive pressure.

- Work Surface Stability: When sharpening, always work on a stable surface. A sturdy table or workbench will minimize vibrations and movement, allowing for more precise sharpening. Make sure the surface is clean and free from distractions to maintain focus.

- Body Positioning: Your body positioning can also contribute to the spear’s stability. Stand or sit in a comfortable position where you can apply even pressure while sharpening. Keep your elbows close to your body to maintain control, and avoid overreaching, which can lead to instability.

- Use of Weights: If additional stability is needed, consider using weights. Placing a weight on the spear’s handle can help keep it steady while you sharpen the tip. Ensure the weight is securely placed to avoid any accidents.

Safety First: Always prioritize safety when securing your spear. Make sure to wear protective gloves and goggles to shield yourself from any accidental slips or sparks that may occur during the sharpening process.

In summary, securing the spear effectively is vital for achieving a sharp edge while ensuring your safety. By utilizing tools like a spear vise, clamps, and ensuring a stable work surface, you can sharpen your spear with confidence and precision. Remember, the right setup can make all the difference in the sharpening experience, leading to a more effective and enjoyable process.

Step 3: Begin Sharpening

With everything set and ready, we can now move on to the crucial phase of sharpening your paralyzer spear. This step is not just about making the spear sharp; it’s about understanding the techniques that will lead to optimal results. The right angle and pressure are essential components in this process.

First, let’s talk about the angle. When sharpening a spear, the ideal angle typically ranges between 20 to 30 degrees. This angle strikes a balance between sharpness and durability. A sharper edge (closer to 20 degrees) can cut through materials easily but may dull faster, while a steeper angle (around 30 degrees) will provide a more robust edge that lasts longer but might require more effort to penetrate.

Next, consider the pressure applied during sharpening. Applying too much pressure can lead to uneven sharpening and may even damage the spear tip. Instead, aim for a consistent, moderate pressure as you move the sharpening tool along the edge. This ensures that you maintain a uniform angle and achieve a smooth finish. If you’re using a file, for example, let the tool do the work; simply guide it along the edge without forcing it.

- Start with the coarse grit: If your spear is significantly dull, begin with a coarse grit to remove material quickly and shape the edge.

- Switch to finer grits: After achieving the desired shape, transition to finer grits to refine the edge and enhance sharpness.

- Maintain a consistent motion: Whether using a file or a whetstone, keep a steady motion to prevent unevenness.

As you sharpen, it’s important to periodically check your progress. Wipe the edge clean to remove any metal filings and visually inspect the sharpness. You can also perform a simple test by gently running your finger (carefully) along the edge to feel for sharpness. Remember, safety first!

Finally, after you’ve sharpened the spear to your satisfaction, it’s crucial to clean the spear thoroughly. This removes any debris and metal shavings that could lead to corrosion. A clean spear not only performs better but also lasts longer.

In conclusion, the sharpening process is an art that requires patience and attention to detail. By focusing on the right angle, applying consistent pressure, and following the proper techniques, you can ensure that your paralyzer spear is ready for action, providing you with the performance you need when it matters most.

Testing the Sharpness

After sharpening your paralyzer spear, it is crucial to ensure that it is adequately sharp for your intended use. Testing the sharpness not only confirms the effectiveness of your sharpening efforts but also guarantees safety during usage. Here, we will explore various methods to test the sharpness of your spear effectively and safely.

Visual Inspection

One of the first steps in testing sharpness is conducting a thorough visual inspection. Look closely at the spear’s blade, focusing on the edge. You should check for any dull spots or inconsistencies which could indicate that the sharpening process was not entirely effective. A sharp spear should have a smooth, uniform edge without any nicks or chips.

To conduct a proper visual inspection:

- Hold the spear under good lighting to better see the edge.

- Run your fingers lightly along the edge, being cautious to avoid cuts.

- Look for reflections on the blade; a dull edge will not reflect light as sharply as a well-honed one.

Cutting Tests

Once you have visually inspected the spear, it’s time to perform practical cutting tests. These tests provide a tangible way to assess the spear’s sharpness. Here are some safe methods for conducting cutting tests:

- Paper Test: Try slicing through a piece of paper. A sharp spear should cut through the paper cleanly without tearing.

- Vegetable Test: Use a soft vegetable, such as a tomato or cucumber. A sharp spear should penetrate the skin easily and slice through with minimal pressure.

- Wood Test: For a more rigorous test, try cutting into a soft piece of wood. This will give you an idea of the spear’s ability to maintain sharpness under more demanding conditions.

Safety Precautions During Testing

While testing the sharpness of your spear, safety should always be a priority. Here are some essential precautions to follow:

- Always test the spear in a controlled environment, away from other people and pets.

- Use protective gear, such as gloves and goggles, to minimize the risk of injury.

- Ensure that the spear is securely held or placed on a stable surface during testing to prevent accidents.

Adjusting Sharpness

If your tests indicate that the spear is not sharp enough, don’t hesitate to return to the sharpening process. Adjust your technique based on the results of your tests. For instance, if the spear struggles to cut through paper, you may need to refine the angle or apply more pressure during sharpening.

In conclusion, testing the sharpness of your paralyzer spear is a vital step in ensuring its performance and safety. Through visual inspections and practical cutting tests, you can confidently assess whether your spear is ready for use. Always remember to prioritize safety during these tests and make adjustments as necessary to maintain optimal sharpness.

Visual Inspection

Conducting a of your paralyzer spear is an essential step in the sharpening process. This assessment allows you to identify any dull spots or inconsistencies that may affect the spear’s performance. A thorough inspection can help ensure that your spear is in optimal condition before you begin sharpening. Here’s a comprehensive guide on what to look for during your assessment.

- Check the Blade Edge: Start by examining the edge of the spear. Look for any nicks, chips, or irregularities. These imperfections can hinder the spear’s cutting ability and may require more extensive sharpening.

- Inspect for Rust: Rust can weaken the metal and compromise the spear’s integrity. Look for any signs of oxidation or discoloration on the blade. If rust is present, it should be addressed before sharpening to prevent further damage.

- Evaluate the Tip: The tip of the spear is crucial for penetration. Ensure that it is pointed and free from any deformities. A damaged tip can lead to ineffective use and may require reshaping.

- Check the Handle: While the focus is often on the blade, the handle is equally important. Ensure that it is secure and free from cracks or splinters. A stable handle provides better control during use.

- Look for Wear Patterns: Analyze the wear patterns on the blade. Uneven wear can indicate improper use or technique. Understanding these patterns can help you adjust your sharpening method for better results.

In addition to these checks, consider the overall condition of the spear. If it has been used extensively, it may require more than just sharpening. Look for signs of fatigue in the material, which could indicate that it’s time for a replacement.

After completing your visual inspection, make note of any areas that require attention. This will guide you as you proceed with the sharpening process. Remember that a well-maintained spear not only performs better but also lasts longer. Taking the time to inspect your spear thoroughly before sharpening can save you from potential issues down the line.

In summary, a is a vital step in maintaining your paralyzer spear. By carefully examining the blade, tip, and handle, you can identify any problems that need to be addressed before sharpening. This proactive approach ensures your spear remains effective and ready for use whenever you need it.

Cutting Tests

Cutting Tests: Evaluating Your Spear’s Sharpness SafelyWhen it comes to ensuring the effectiveness of your paralyzer spear, testing its sharpness through is an essential step. This practical evaluation not only confirms the sharpness but also enhances your confidence in using the spear for its intended purpose. In this section, we will explore safe methods for conducting cutting tests, ensuring that you can assess your spear’s cutting ability without compromising safety.

Why Conduct Cutting Tests?

Cutting tests serve a dual purpose: they provide a tangible measure of sharpness and help you understand how the spear performs under realistic conditions. A sharp spear is crucial for effective penetration and clean cuts, which are vital in various applications, from fishing to hunting. Understanding the spear’s performance through cutting tests can also guide you in making necessary adjustments during the sharpening process.

Safe Methods for Testing Sharpness

Before you start performing cutting tests, it’s important to prioritize safety. Here are some methods to safely evaluate your spear’s sharpness:

- Paper Test: One of the simplest methods is to slice through a piece of paper. Hold the paper firmly and attempt to cut through it with the spear’s edge. A sharp spear should easily slice through the paper with minimal resistance.

- Vegetable Test: Use soft vegetables like tomatoes or cucumbers for a more practical test. These materials mimic the resistance you might encounter in real-world scenarios. A sharp spear should penetrate smoothly without excessive force.

- Wood Test: For a more rigorous evaluation, try slicing through a piece of soft wood, such as balsa. This test will provide feedback on how well the spear maintains its edge under more demanding conditions.

Performing the Tests

When conducting these tests, ensure you have a stable and secure surface. Here are some tips to keep in mind:

- Always wear protective gear, such as gloves and safety glasses, to protect yourself from accidental slips.

- Secure the spear firmly to prevent it from moving during the test. A vice or a stable workbench can be very helpful.

- Maintain a safe distance from others while performing the tests to avoid any potential accidents.

Assessing the Results

After conducting the cutting tests, evaluate the results critically:

- Clean Cuts: If the spear creates clean, effortless cuts, it indicates that the edge is sharp and ready for use.

- Dull Spots: If you notice any resistance or jagged cuts, inspect the spear for dull spots that may need further sharpening.

- Consistency: Test multiple areas of the blade to ensure uniform sharpness across the entire edge.

By following these guidelines for cutting tests, you can safely assess your paralyzer spear’s sharpness and ensure it is optimized for performance. Remember, regular testing and maintenance are key to prolonging the life and effectiveness of your spear.

Maintenance Tips for Longevity

Proper maintenance is crucial for prolonging the life of your paralyzer spear. By following these essential tips, you can ensure that your spear remains in top condition after sharpening, ready for your next adventure.

Regular Cleaning

After each use, it is important to clean your spear thoroughly. This prevents rust and corrosion, which can significantly affect performance. Use fresh water to rinse off any salt, sand, or debris that may have accumulated during your outing. A soft cloth or sponge is ideal for this task. For tougher stains or residues, consider using a mild soap solution. Always dry your spear completely with a clean cloth to avoid moisture retention.

Inspect for Damage

Regular inspections are vital to maintaining your spear’s integrity. Look for any signs of wear, such as dents, bends, or rust spots. Addressing these issues early can prevent further damage. If you notice any significant damage, consider consulting a professional for repairs. Keeping your spear in optimal condition ensures better performance and safety during use.

Storage Solutions

How you store your spear can greatly impact its longevity. When not in use, store your spear in a dry, cool place away from direct sunlight. Consider using a protective sheath or case to prevent accidental damage and exposure to the elements. If possible, hang your spear vertically to avoid bending or warping. Ensure that it is secure and not in contact with other sharp objects that could cause scratches or dents.

Routine Maintenance Checks

In addition to cleaning and inspections, performing routine maintenance checks can help keep your spear in excellent condition. This includes checking the sharpness of the tip and ensuring that the barbs are intact. If you notice any dullness, follow the sharpening process to restore its edge. Keeping a maintenance schedule can help you stay on top of these tasks.

Use of Protective Coatings

Applying a protective coating to your spear can provide an extra layer of defense against corrosion and wear. Consider using a rust-resistant spray or oil specifically designed for metal surfaces. This can help maintain the spear’s appearance and functionality over time. Be sure to follow the manufacturer’s instructions for application to achieve the best results.

Seasonal Maintenance

Depending on how often you use your spear, consider conducting a more thorough maintenance routine at the beginning and end of each season. This includes deep cleaning, inspections, and any necessary repairs. Preparing your spear for seasonal use ensures that it is ready for action when you are. Additionally, after a season of use, take the time to address any wear and tear that may have occurred.

Conclusion

By implementing these maintenance tips, you can significantly extend the life of your paralyzer spear. Regular cleaning, inspections, proper storage, and routine checks will ensure that your spear remains an effective tool for all your spearfishing adventures.

Regular Cleaning

Cleaning your spear after each use is not just a good practice; it’s essential for preserving its functionality and extending its lifespan. A well-maintained spear not only performs better but also resists rust and damage, ensuring that you can rely on it during your spearfishing adventures. Below are effective cleaning methods that will help maintain the spear’s integrity.

After each use, your spear is exposed to saltwater, dirt, and other contaminants that can lead to corrosion and wear if not properly addressed. Regular cleaning helps to:

- Prevent Rust: Saltwater can quickly corrode metal surfaces, leading to rust formation.

- Maintain Performance: A clean spear performs better, providing more accurate and effective thrusts.

- Extend Lifespan: Regular maintenance ensures that your investment lasts longer, saving you money in the long run.

Here are some practical cleaning methods to keep your spear in optimal condition:

Immediately after use, rinse your spear with fresh water. This simple step removes salt and debris, preventing corrosion. Use a soft cloth to wipe down the shaft and tips gently.

For a more thorough clean, use a mild soap solution. Mix a few drops of dish soap with water and use a sponge to scrub the spear gently. Pay special attention to any crevices where dirt can accumulate. Rinse thoroughly to remove any soap residue.

After rinsing, it’s crucial to dry your spear completely. Use a clean, dry cloth to wipe it down. If possible, allow it to air dry in a well-ventilated area. Moisture left on the spear can lead to rust formation.

While cleaning, take the time to inspect your spear for any signs of damage, such as nicks or bends. Addressing these issues early can prevent further damage and ensure your spear remains safe to use.

In addition to regular cleaning, consider the following tips to enhance your spear’s longevity:

- Lubrication: Applying a light coat of oil to metal parts can provide a protective barrier against moisture.

- Storage: Store your spear in a dry place, preferably in a protective case to avoid accidental damage.

- Regular Inspections: Periodically check your spear for wear and tear, even if it hasn’t been used for a while.

By adopting these cleaning practices and maintenance tips, you can ensure that your spear remains in excellent condition, ready for your next underwater adventure. Remember, a clean spear is a reliable spear!

Storage Solutions

When it comes to maintaining the condition of your paralyzer spear, how you store it is crucial. Proper storage not only preserves the spear’s sharpness but also prevents damage from environmental factors. Here are some effective storage options and tips to ensure your spear remains in optimal condition.

- Dry and Cool Environment: Always store your spear in a dry and cool place. Humidity can lead to rust and corrosion, especially if your spear has metal components. A temperature-controlled area is ideal.

- Use a Protective Case: Investing in a high-quality protective case can shield your spear from physical damage. Look for cases that have padding and are water-resistant to provide extra protection.

- Vertical Storage: Storing your spear vertically can help prevent bending and damage to the tip. Consider using a wall-mounted rack or a dedicated spear stand to keep it upright.

- Avoid Direct Sunlight: Prolonged exposure to sunlight can degrade materials and cause fading. Store your spear in a shaded area or inside a case to protect it from UV rays.

- Regular Inspections: Periodically check your spear for any signs of wear, rust, or damage. Early detection can help you address issues before they become serious problems.

Why Is Proper Storage Important?

Proper storage is essential for several reasons:

- Prevents Rust and Corrosion: Metal parts can easily rust if not stored correctly. By keeping your spear dry and protected, you minimize the risk of corrosion.

- Maintains Sharpness: Storing your spear in a way that protects the tip will help maintain its sharpness, ensuring it’s always ready for use.

- Extends Lifespan: Proper care and storage can significantly extend the lifespan of your spear, saving you money in the long run.

Additional Tips for Effective Storage

To further enhance your spear’s storage, consider these additional tips:

- Wrap the spear tip in protective material to prevent accidental damage.- Keep the spear away from other tools to avoid scratches and dents.- Consider using silica gel packets in your storage area to absorb excess moisture.

In summary, the way you store your paralyzer spear can significantly impact its longevity and performance. By following these recommendations, you can ensure that your spear remains in excellent condition, ready for your next adventure.

Common Mistakes to Avoid

Common Mistakes to Avoid When Sharpening a Paralyzer SpearSharpening a paralyzer spear can be a rewarding task, but even seasoned users can encounter pitfalls that compromise the spear’s effectiveness. Understanding these common mistakes is essential for achieving a successful sharpening experience. Below, we outline some of the most frequent errors and provide guidance on how to avoid them.

- Over-Sharpening: One of the most prevalent mistakes is over-sharpening the spear. This can lead to a weakened tip and an uneven edge, making the spear less effective. To prevent this, it is crucial to frequently check the sharpness during the process. Aim for a fine edge but stop once you feel the spear is adequately sharpened.

- Using the Wrong Tools: Not all sharpening tools are suitable for every spear type. Using inappropriate tools can lead to poor results and potential damage. Always assess the material and design of your spear before selecting a sharpening tool. For instance, a fine whetstone may be ideal for some materials, while others might require a coarser file.

- Incorrect Angle: Maintaining the correct sharpening angle is vital for achieving a sharp edge. Many users inadvertently change the angle while sharpening, leading to uneven edges. A consistent angle of approximately 20 degrees is typically recommended. Using a guide can help maintain this angle throughout the sharpening process.

- Neglecting Safety Precautions: Safety should never be overlooked. Failing to wear protective gear, such as gloves and eye protection, can lead to injuries. Always ensure your workspace is organized and free from distractions to maintain focus while sharpening.

- Ignoring Regular Maintenance: After sharpening, many users neglect the maintenance of their spear. Regular cleaning and proper storage are essential for prolonging the spear’s lifespan. Make it a habit to clean the spear after each use and store it in a dry place to prevent rust and damage.

- Rushing the Process: Sharpening should not be a hurried task. Taking your time allows for more precise work and better results. Rushing can lead to mistakes, such as uneven edges or damage to the spear. Set aside enough time to complete the sharpening without feeling pressured.

- Failing to Test Sharpness: After sharpening, it’s crucial to test the spear’s sharpness before use. Skipping this step can result in a spear that is not ready for action. Employ safe methods to test sharpness, such as slicing through soft materials to gauge effectiveness.

By being aware of these common mistakes and taking proactive measures to avoid them, you can ensure a more successful sharpening experience. Remember, sharpening is both an art and a science that requires practice and attention to detail. With patience and the right approach, you can keep your paralyzer spear in peak condition, ready for your next adventure.

Over-Sharpening

Over-Sharpening: Recognizing the Signs and Avoiding DamageWhen it comes to sharpening a paralyzer spear, is one of the most frequently encountered issues. This common mistake can lead to significant damage to the spear, affecting its performance and longevity. Understanding how to identify when you have sharpened enough is crucial for maintaining the integrity of your spear.

Over-sharpening occurs when excessive material is removed from the blade’s edge, resulting in a thin and fragile tip. This can make the spear more susceptible to bending or breaking during use. To avoid this, it is important to recognize the signs that indicate sufficient sharpening has been achieved.

- Visual Inspection: Regularly inspect the spear’s edge as you sharpen. Look for a consistent angle and a smooth surface. If you notice that the edge is becoming excessively thin or uneven, it may be time to stop.

- Touch Test: Gently run your finger along the edge of the spear. It should feel sharp but not overly jagged. If it feels too sharp or has a serrated texture, you may have overdone it.

- Cutting Performance: After sharpening, test the spear’s cutting ability on a suitable material. If it cuts cleanly without requiring excessive pressure, you’ve likely sharpened enough. If it struggles or feels dull, you may need to reassess your sharpening technique.

To prevent over-sharpening, consider the following tips:

- Use the Right Tools: Ensure you are using appropriate sharpening tools that match the spear’s material. Using the wrong tool can lead to uneven sharpening and increase the risk of over-sharpening.

- Sharpen in Stages: Instead of attempting to achieve a razor-sharp edge in one go, sharpen in stages. This allows you to check the edge frequently and avoid removing too much material at once.

- Follow Manufacturer Guidelines: If available, refer to the manufacturer’s instructions for sharpening. They often provide specific recommendations for maintaining the spear’s edge without causing damage.

In conclusion, avoiding over-sharpening is essential for preserving the functionality of your paralyzer spear. By paying attention to the signs of sufficient sharpening and following best practices, you can ensure that your spear remains effective and durable for all your spearfishing adventures.

Using the Wrong Tools

Using inappropriate tools can lead to poor results and potential damage. This section will discuss how to choose the right tools for your specific spear type, particularly focusing on the paralyzer spear.

- Understanding Your Spear Type: Before selecting any tools, it’s crucial to understand the specific characteristics of your paralyzer spear. Paralyzer spears are designed with multiple prongs, which require precise sharpening techniques and tools. Using tools meant for single-point spears can lead to uneven edges and reduced effectiveness.

- Identifying Suitable Sharpening Tools: The choice of sharpening tools is paramount. For paralyzer spears, tools such as fine files, diamond sharpeners, and whetstones are often recommended. Each tool serves a specific purpose:

- Fine Files: These are excellent for achieving a sharp edge on metal tips. They provide control and precision, allowing you to work on the intricate prongs of the spear.

- Diamond Sharpeners: These are durable and effective for sharpening harder materials. They can quickly restore an edge without excessive wear on the spear.

- Whetstones: While they require more skill, whetstones can produce a razor-sharp edge when used correctly. They are versatile and can be used for various materials.

- Assessing Your Skill Level: It’s essential to consider your skill level when choosing sharpening tools. Beginners might find files easier to handle, while experienced users may prefer whetstones for their versatility. Using a tool that matches your skill set can enhance the sharpening process and prevent damage to the spear.

- Tool Maintenance: Ensuring your sharpening tools are in good condition is vital. Dull or damaged tools can lead to poor sharpening results. Regularly inspect and maintain your tools to ensure they perform optimally.

- Common Mistakes to Avoid:

- Using tools designed for different spear types can lead to poor outcomes. Always select tools that are specifically designed for paralyzer spears.

- Neglecting the importance of grit selection can result in ineffective sharpening. Understanding the appropriate grit for your tool and spear material is crucial.

In summary, selecting the right tools for sharpening your paralyzer spear is critical for achieving optimal results. By understanding your spear type, choosing suitable tools, and considering your skill level, you can avoid the pitfalls associated with using the wrong tools. This thoughtful approach will ensure that your spear remains effective and ready for use when needed.

Conclusion: Mastering the Art of Sharpening

Sharpening a paralyzer spear is not just a skill; it’s an art form that can significantly enhance your spearfishing experience. This essential skill ensures that your spear is always in optimal condition, ready to perform when you need it most. By mastering the techniques outlined below, you can maintain the effectiveness and longevity of your spear, making each dive more successful.

Before diving into the sharpening process, it’s vital to understand why this practice is crucial. A well-sharpened spear enables precise targeting, increases penetration power, and enhances overall performance. Dull tips can lead to missed opportunities and unsuccessful hunts, making sharpening an indispensable part of your spearfishing routine.

- Files: Ideal for precision sharpening, files allow you to control the angle and pressure applied to the spear tip.

- Whetstones: These versatile tools provide a fine edge and are suitable for various materials, though they require some practice.

- Electric sharpeners: For those who prefer speed, electric sharpeners can quickly bring a dull spear back to life, but caution is advised to avoid over-sharpening.

A well-organized workspace is crucial for effective sharpening. Ensure you have adequate lighting and a stable surface to work on. This not only enhances safety but also improves your accuracy during the sharpening process. Always wear protective gear, such as gloves and goggles, to safeguard against accidents.

The sharpening process can be broken down into a few key steps:

- Inspect the spear: Look for any signs of damage or wear before you begin.

- Secure the spear: Use a clamp or vice to hold the spear in place, ensuring your hands are free to work safely.

- Sharpen the tip: Using your chosen tool, maintain a consistent angle as you sharpen the spear tip, applying even pressure.

After sharpening, it’s essential to test the spear’s sharpness. A simple visual inspection can reveal dull spots, while cutting tests on soft materials can provide practical feedback on the spear’s cutting ability. Always prioritize safety during these tests to prevent injury.

To ensure your paralyzer spear remains in top condition, regular maintenance is key. Clean your spear after each use to prevent rust and corrosion. Store it in a dry place, preferably in a protective sheath, to avoid damage during transport. Regularly inspect the spear for any signs of wear or damage, addressing issues promptly to prolong its lifespan.

Even seasoned spearfishers can make errors during the sharpening process. Avoid over-sharpening, which can weaken the spear tip and lead to breakage. Additionally, using the wrong tools can result in poor outcomes, so always select tools appropriate for your spear material.

By following these comprehensive guidelines and tips, you can master the art of sharpening your paralyzer spear. This skill not only enhances your performance but also ensures that you are always prepared for your next underwater adventure.

Frequently Asked Questions

- What is a paralyzer spear?

A paralyzer spear is a specialized fishing spear designed to immobilize fish without causing significant harm. Its unique tip features multiple prongs that spread out upon impact, ensuring a secure catch while minimizing damage to the fish.

- What tools do I need to sharpen a paralyzer spear?

To sharpen a paralyzer spear, you will need essential tools like files, whetstones, and possibly an electric sharpener. Each tool has its benefits, so choose one based on your comfort level and the spear’s material.

- How often should I sharpen my paralyzer spear?

It’s best to sharpen your paralyzer spear regularly, especially after multiple uses or if you notice a decrease in performance. A quick inspection after each fishing trip can help you determine when sharpening is needed.

- What are the safety precautions I should take while sharpening?

Always wear protective gloves and eyewear when sharpening to prevent injuries. Make sure your workspace is well-lit and stable, and secure the spear properly to avoid accidents during the sharpening process.

- How can I test the sharpness of my spear?

After sharpening, you can test the spear’s sharpness through visual inspections for any dull spots and by performing cutting tests on soft materials. This will give you a practical sense of how well your spear is performing.